Bennett’s Customs - Headlight Reflector Bezel

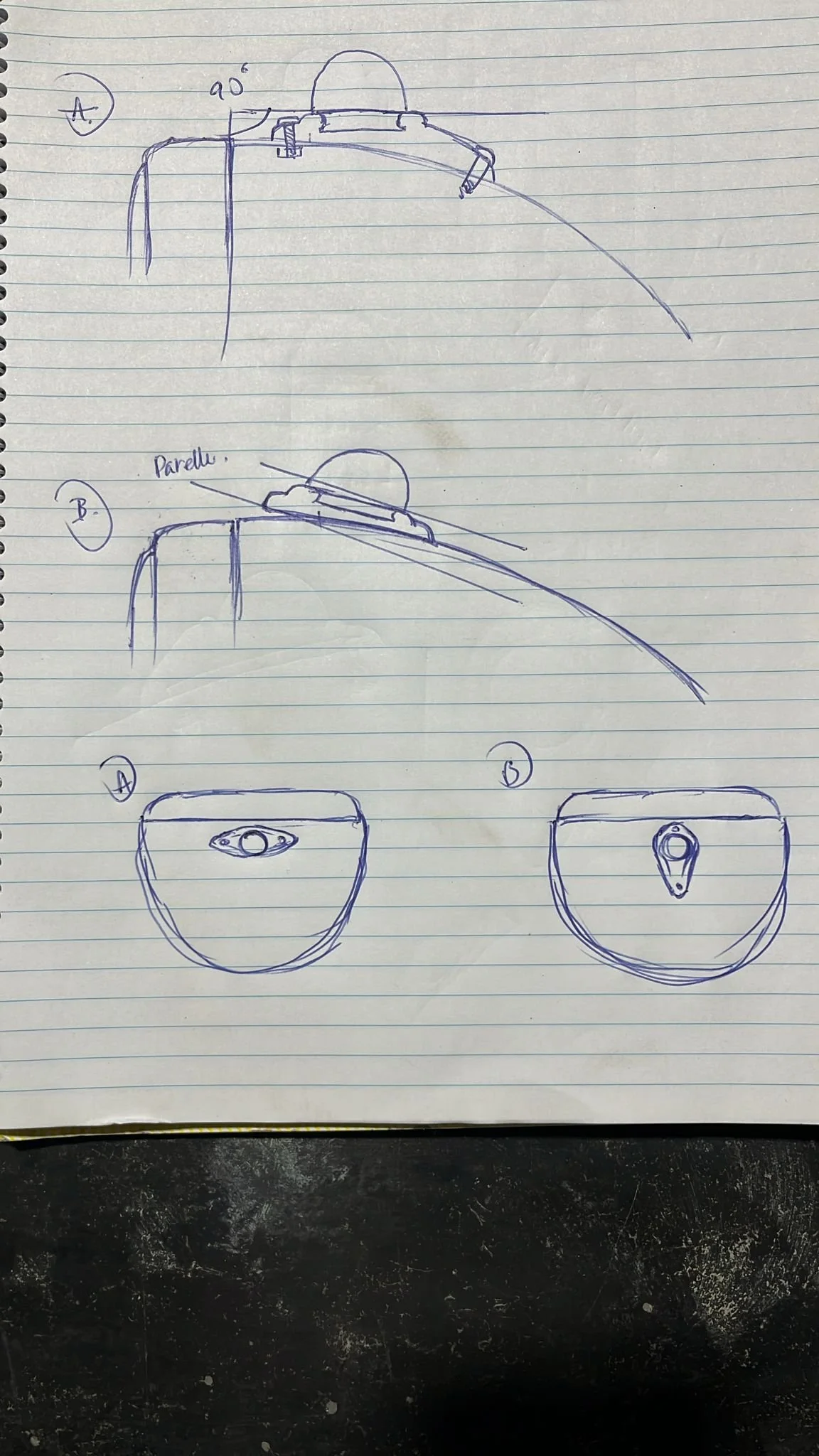

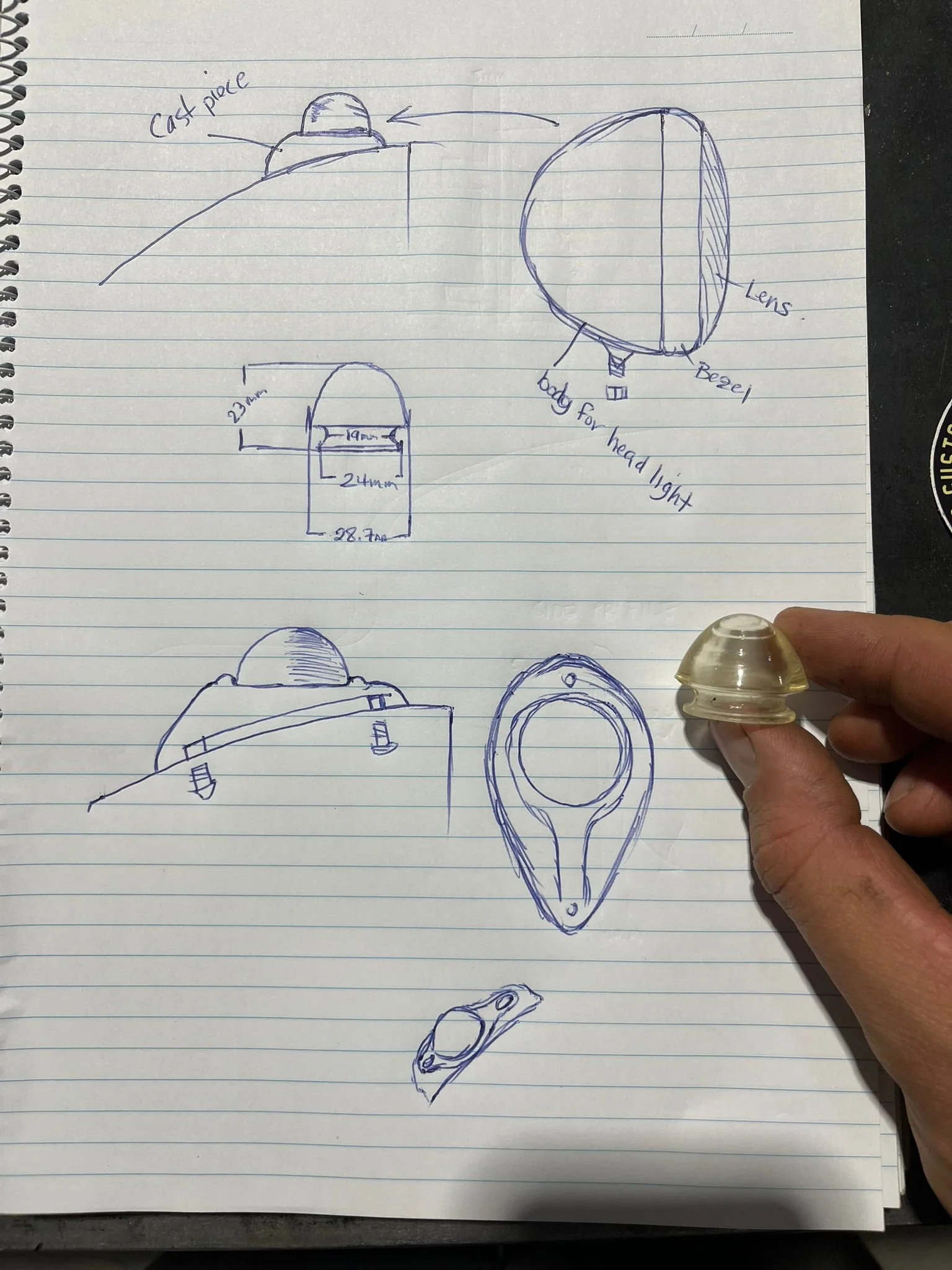

This project started with an idea to add a small reflector to a Ford headlight bezel. The position of the reflector was defined and I was provided with some sketches on how it should function. We wanted to produce a cast part that would mount directly to the headlight and house the reflector. It was important that the part blended into the original style of the car and look like it was an original piece.

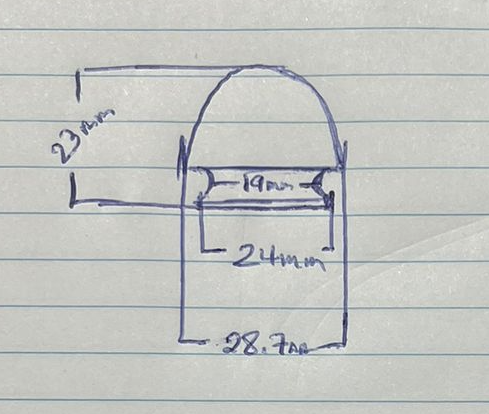

The original sketches and pictures allowed for a guide on the look the part needed to have as well as a general position of the reflector. As I was not able to be onsite and measure the headlight the next important step was to get accurate dimensions of both the headlight and the reflector. For all remote projects this is the most crucial step as without an accurate reference it is impossible to produce an accurate final design.

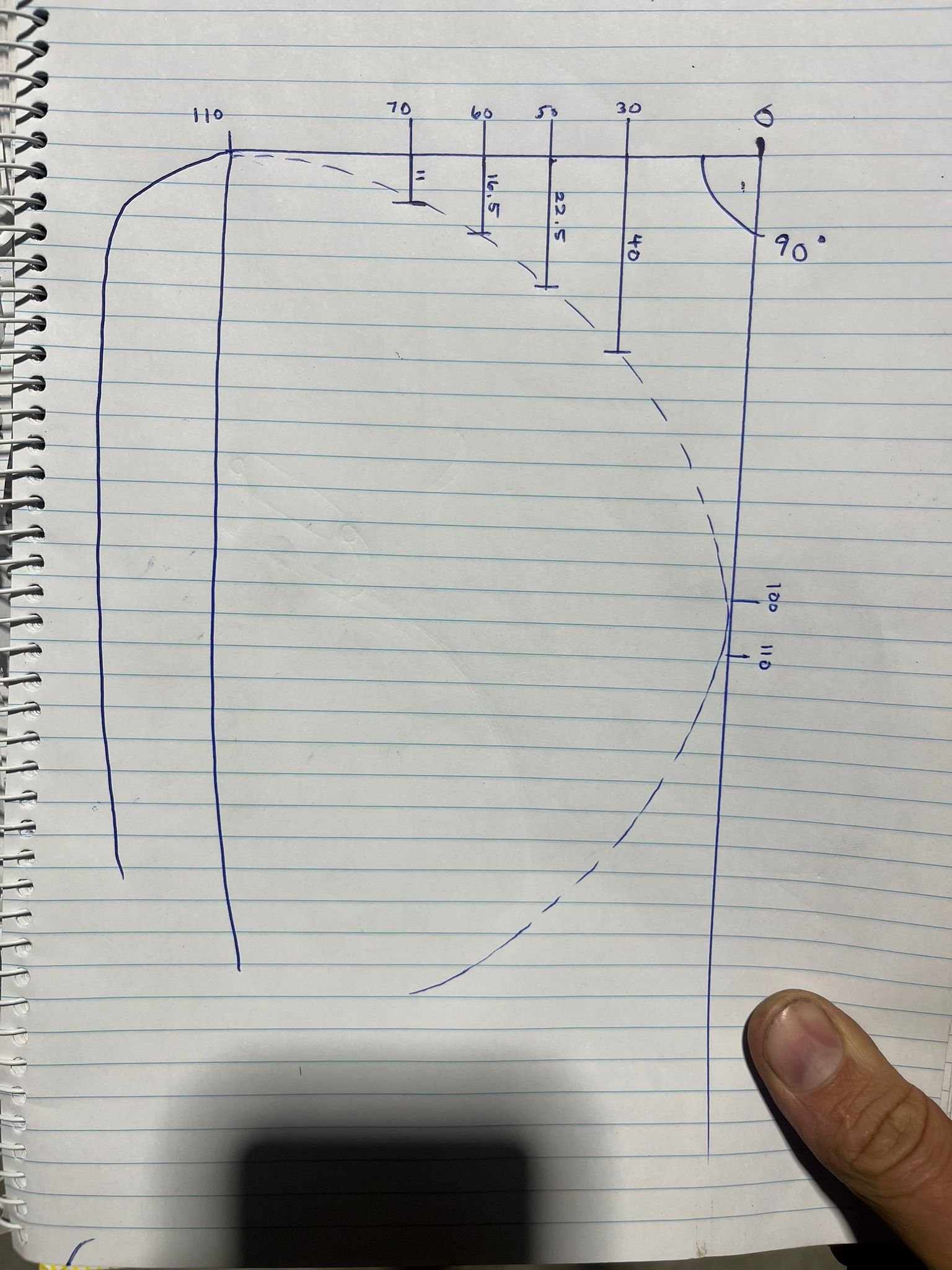

After discussing the design the sketches were provided with accurate measurements. These sketches are used to create an accurate reference model of the headlight and the reflector. The surfaces can also be used to model the part. This may take some back and forth to make sure an exact fit, this can involve 3D printing or templates.

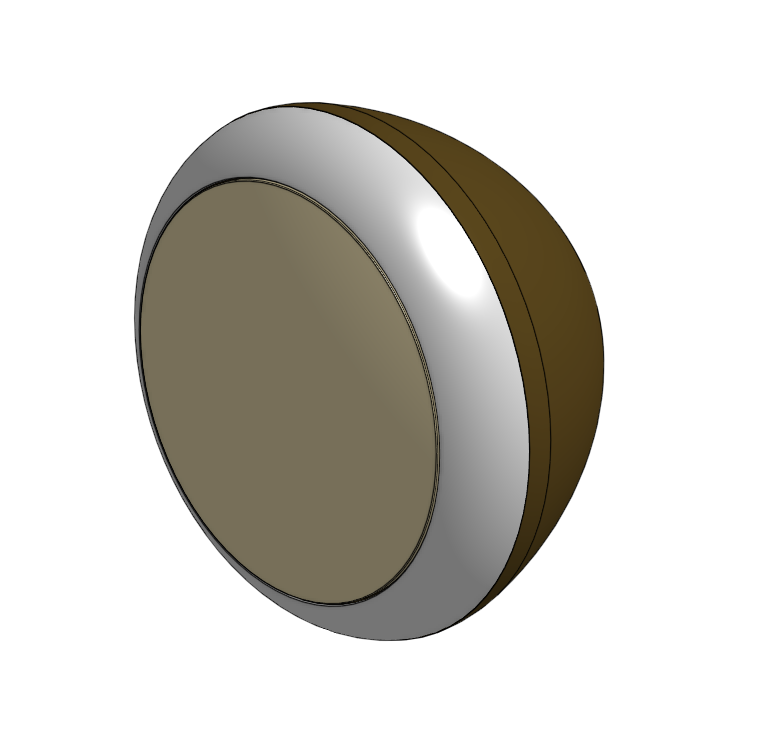

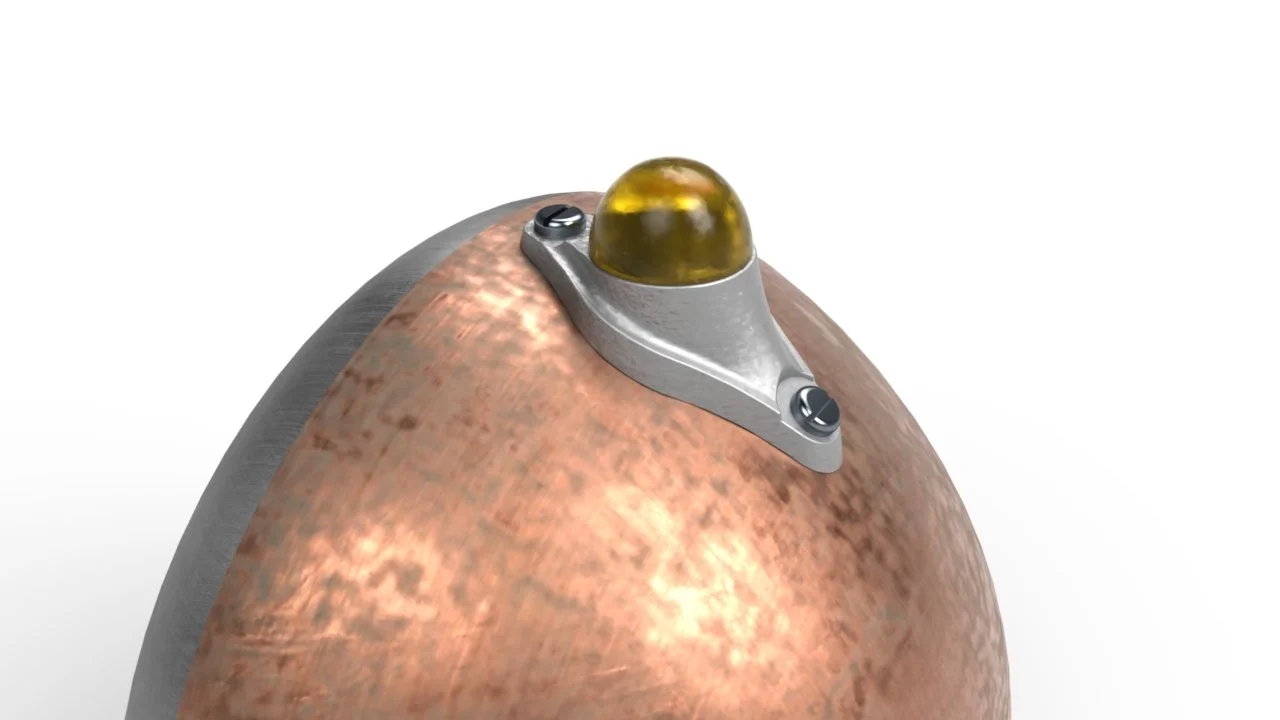

The design and modelling process can begin. This part was modelled in Onshape using parametric and surface modelling. There are some quite complicated surfaces to allow for the casted vintage look. In addition to the shape it must be taken into account how the part will be mounted and the fitment of the reflector.

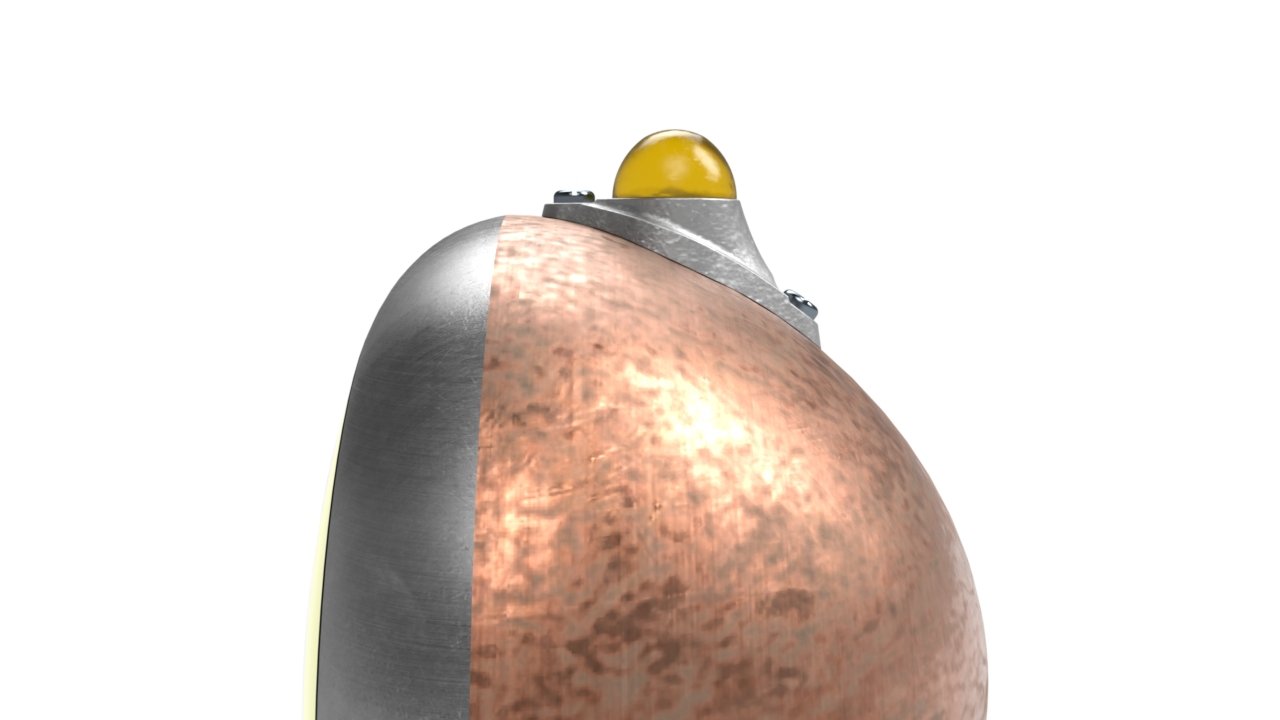

Above shows a render of the final design. It was tricky to get all of the curves flowing. The headlight has quite a bit of curve and that needed to be transitioned into a flat face of the reflector. The next step of the process was to have the piece 3d printed to check fitment and be used as a plug.

A bunch of these have been 3D printed. Casting can be a tricky process and it is better to have a few back ups just in case something goes wrong. The extras also allow for them to be produced as a batch. The 3d printed surface can be seen in the picture. In order to get a perfect part after casting the layer lines from the print will need to be sanded an prepped. Everything that is present in this plug will be taken over into the final part.

The video here shows the final fitment of the part. The mount sits nicely on the headlight and the reflector fits. At this stage Jordan is still working on the parts and will be casting this part in the next few weeks. If you want to keep up to date on this head over to Bennett’s Customs on Instagram or Youtube.